Breen Machine Provides OEM Automation Project Support to Solve OEM Capacity Problems

Summary

An OEM had more projects than capacity. Breen Machine Automation Services worked as part of the team filling a variety of roles including electrical design, panel assembly, machine wiring, programming, and debug.

Key Benefits

- Provided timely expertise

- Added resources for peak project volume

- Accelerated schedule and improved customer experience

Technologies used

- Yamaha SCARA robot

- Cognex camera for robot guidance

- Allen Bradley CompactLogix PLC

- Allen Bradley PanelView HMI

The Breen Machine Solution

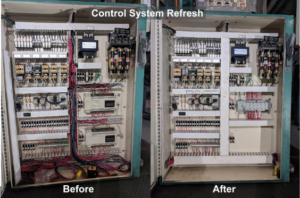

Capital projects in the automation industry tend to come in waves, and sometimes OEMs find themselves with more work than they can handle. While bidding on a custom medical assembly automation project, an OEM found it didn’t have the capacity to meet its customer’s deadlines, so Breen Machine was consulted to help secure the project. Together, we integrated a vision-guided robot, part-feeding device, pneumatics, PLC, and HMI.

When the project started, we worked as part of the OEM’s team, taking the lead on controls. First, we worked with the mechanical designers to offer a controls perspective to their efforts. When the mechanical design was ready, we designed and built the electrical portion. We installed the panel and wired the machine, then loaded our custom programs to start troubleshooting. Breen Machine led the debug efforts, testing, quantifying, and refining the process toward project goals. We followed the project through to completion with runoff at the machine builder’s site and installation at their customer’s site.

Custom automation always brings unique challenges with it, requiring strong, multidisciplinary troubleshooting skills and a focus on project goals. To complicate things, building a team with the right talent and communication to execute a custom automation project often takes a lot of time and care. Breen Machine’s broad expertise and strong teamwork made this collaboration possible, as it has many times before.

Are you an OEM? Let’s chat before the busy time hits. It’s always good to know what resources are available.

About the Author

Jon is an engineer, entrepreneur, and teacher. His passion is creating and improving the systems that enhance human life, from automating repetitive tasks to empowering people in their careers. In his spare time, Jon enjoys engineering biological systems in his yard (gardening).