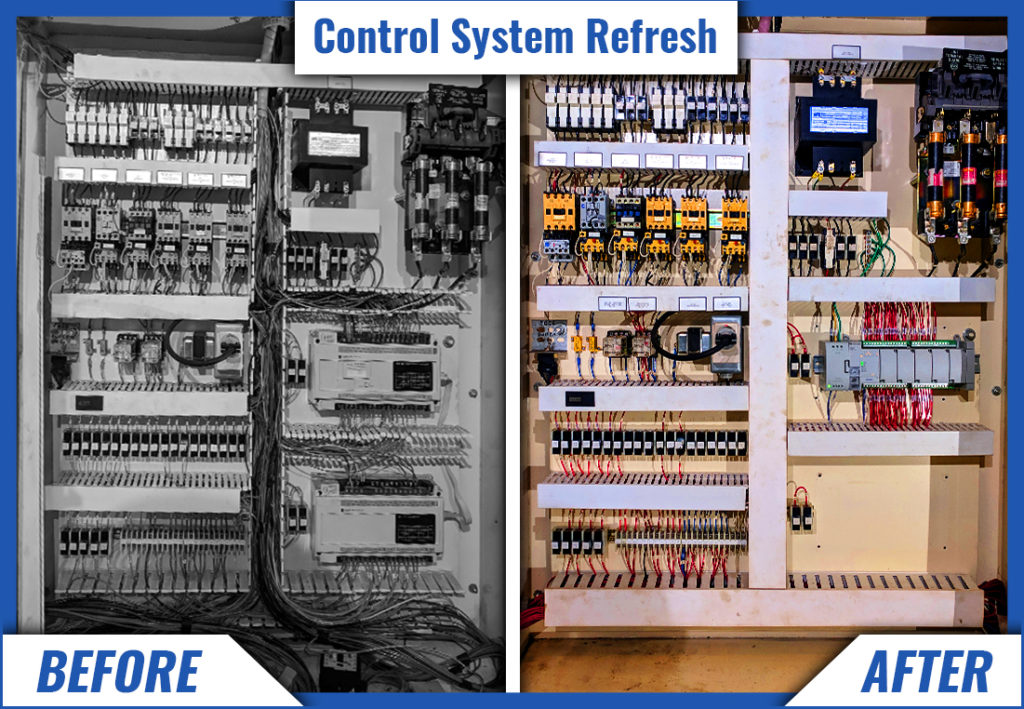

Update Aging Control Systems for Peace of Mind

Any piece of automation ages – tooling wears out, belts break, bearings seize – but the control systems age in a unique way. Bearings and belts are governed by long-standing standards. People know what they are, how to maintain or replace them, and replacement parts are readily available for many years after the machine was built. Control systems, on the other hand, are evolving much more rapidly – better processors, more memory, faster and more convenient communications, and new programming standards. This brings innumerable benefits, but it makes long-term maintenance more difficult. The older parts aren’t made anymore, and few people know how to work with them. This usually starts to cause problems 20-30 years into the equipment’s life.

There’s no reason to replace the whole machine or even the whole electrical system. A targeted upgrade can be very economical and extend the maintainable life of your equipment for another 20-30 years.

Benefits of Updating

Running a machine with an obsolete control system can be a nightmare. What happens if a part fails and you can’t get a new one quickly? Do you have the old software, cables, and a compatible laptop to connect? Updating the control system makes your life easier.

- More maintainable

- Better uptime

- Parts are readily available

- People know how to work with it

- More flexibility

- Performance enhancements are virtually free

The Breen Machine Advantage

We start by thoroughly understanding your needs. Our extensive experience helps us ask the right questions, foresee and avoid issues, and guide the process to a smooth conclusion. Good planning minimizes downtime and maximizes process improvement. Our targeted approach and expertise also save time and money. Our customers have told us we’re 3 times faster and 75% cheaper than other options.

We work with any brand and model of PLC. Some common examples include Allen Bradley SLC150, SLC500, and PLC5, Omron Sysmac, and Mitsubishi Melsec.

Contact Us

What people are saying

Our typical services for control system updates

- Accurate timeline and budget planning

- Reverse engineer existing system

- Hardware selection

- Electrical design and documentation

- Panel build

- Programming you can understand

- Performance enhancements

- Installation and testing

- Training and support

Free resources

If you’re considering a controls upgrade, you may be interested in seeing what the process looks like and what other considerations come into play. Check out our other articles and videos related to this topic:

- Article: How to upgrade an obsolete PLC

- Video: Upgrading a SLC150 PLC

- Video: Choosing new hardware for SLC150 upgrade

- Video: Upgrading the program in a SLC150 upgrade

- Article: Upgrade or convert the PLC program

- Article: When is it Time to Upgrade?

And don’t forget, we’re a resource as well! Let us make the process easy. We’re happy to help and quotes are free.