This post is part of a series of thoughts from BMAS founder/owner Jon Breen on how we learn in industry and how that’s changing. Check out all the posts in our Brain Outside Your Brain series.

Brain Outside Your Brain (BOYB) Training

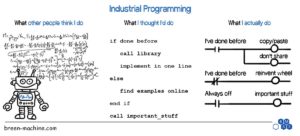

I’ve talked before about the limits of the human brain and how we often outsource our memory to non-brain media, from simple notebooks and calendars to more advanced electronic means (Brain Outside Your Brain, BOYB). I’ve also talked about how we’re required to constantly learn new things to keep pace with technology in our careers (see Help! My Job’s Changing Too Fast and Reducing Information Overload). Here, I’m going to tie these two ideas together in a pitch for what I consider the future of industrial automation training. What types of job-related information can we outsource? Can we wait to learn something until we actually need to know it? What would that look like?

Standard Industrial Automation Training Processes

Standard industrial automation training approaches revolve around in-person, scheduled training programs, usually through a supplier or manufacturer. These have been valuable additions to the workforce’s skill set, but they come with limitations. They’re only offered at certain times, often require travel, require a person to commit to the whole course in one sitting, and can be quite expensive. If you want to have the knowledge necessary for a project, you have to plan well in advance, binge the material all at once, and hope your memory and notes are up to the task when it comes time to implement. Because of these limitations, people often aren’t getting training that would help them, and even if they got the training, they’ve often forgotten much of it by the time they need it. I think this is a perfect opportunity to improve things with the BOYB (Brain Outside Your Brain) approach.

We’re all familiar with this approach to learning, whether we know it or not. We use technology every day to understand things we’ve never learned. Let’s explore that with a few targeted questions.

- Have you ever had a home improvement project, car issue, gardening interest, or curiosity about the newest electronic gadget?

- Did you go to school and get a degree in each one of those things just in case you ever needed to know about them?

- If you were to do that, would you remember what you need to know when the time came?

- Would the knowledge still be relevant?

I think the answers are universally “no” for all these questions. Of course you didn’t get a degree in every life skill you might need. You wouldn’t remember what you learned if you did, and the information would likely be obsolete by the time you needed it anyway (especially where technology is concerned).

Industrial Automation Training Processes in 2018

Twenty years ago, most of us probably outsourced these skills to other people. For example, you might call your uncle Jim, a plumber, when you need to install a new faucet. Today, most of us turn to the internet for DIY solutions, with uncle Jim reserved for the hard stuff. For example, YouTube has tutorials for every home improvement project imaginable. You can watch them right before you do the project, so you’ll remember it. You also don’t have to plan very far in advance because the video tutorial will always be right at your fingertips.

We’re starting to see this same type of BOYB “training” available for industrial topics as well. Manufacturers like Omron Automation, Rockwell Automation, and Phoenix Contact are dipping their toes in the water, making short videos such as how-tos, product demos, selection guides, etc. They tend to be product-specific and limited in scope. I’d also expect they won’t address any product shortcomings or related real-life scenarios since they have an interest in selling the products. I’m also seeing schools (Ivy Tech) and individuals (PLC Professor) posting content that approaches the topic from other angles. This is undoubtedly an area we’ll see a lot of growth in over the next few years.

The Future of Industrial Automation Training

I expect a lot of growth in the near future in two distinct areas of BOYB training for industry professionals: quick reference and skills development.

Quick reference refers to training that helps someone immediately. This is usually a short video that helps a person dealing with a very specific task. For example, let’s say a PLC dies in a piece of automation. The program has been backed up and there’s a spare PLC on the shelf, but the technician doesn’t do this very often and can’t remember how to load the program. Automation downtime can be very costly, so it’s important to get this fixed ASAP. The technician could look through manuals, or find an on-demand course on PLCs, but that would take a fair amount of time. The best thing would be a quick video on downloading PLC programs to that kind of PLC. Access to short, specific videos like this expands what a person can do in his/her job, today.

The second area I expect to see grow focuses on skill development. These BOYB trainings will likely focus on broader topics like vision inspection, industrial Ethernet, PLC programming, etc. You might think of them in similar terms to the traditional in-person seminars offered by manufacturers and distributors, but I expect they’ll be more of a parallel path. They’ll be much more accessible in terms of cost, scheduling, and geography, so they’ll probably be utilized more. On the other hand, they don’t offer the hands-on experience that an in-person training might, so I think the two will be complementary approaches.

Scalable Training – for Pros, by Pros

Here at Breen Machine, we believe everyone should be able to learn and grow at their own pace, on their own time, and without breaking the bank. That’s why we’re developing training materials to address both the immediate and future needs of industrial automation professionals, students, and companies. Check out our training at Breen-Machine.com/training.

We Want to Hear From You!

What skills would improve your career? What kinds of how-to trainings would help you out of a bind? Let us know at info@breen-machine.com or by commenting below.

About the Author

Jon is an engineer, entrepreneur, and teacher. His passion is creating and improving the systems that enhance human life, from automating repetitive tasks to empowering people in their careers. In his spare time, Jon enjoys engineering biological systems in his yard (gardening).